This write-up was created by Wine Country Pools and

Supplies a pool service company located in Temecula California (Our website can be found here at www.WCPandS.com). It will cover

changing the turbine and flaps on a Pool Cleaner by Poolverbnuegen. The version

of Pool Cleaner does not matter, the steps shown here would be the same for all

models. Over time, the connectors holding the flaps can become loose, causing

the flaps to stop the turbine from moving. The replacement part number is 896584000-365

(SCP part number PVN-201-1004), and includes no instructions. This guide will

show how we changed the turbine and flaps on one of these cleaners.

Parts needed:

1) Poolvergnuegen Turbine Hub and Vane Kit #896584000-365

2) Hammer

3) Allen wrench (5/32) also known as hex key or allen key

4) Phillips head screw driver (hopefully it is small enough

to fit though the center rod of the pool cleaner, that step will be seen later,

otherwise a small screwdriver will also be needed)

5) Needle nose pliers

To begin, remove the 3 Phillips head screws holding the top

shell of the Pool Cleaner on.

Once the screws are removed, the top shell can be pulled up

and off of the cleaner.

Pull the center cone up and off of the cleaner, the turbine

is just under this.

The turbine flaps need to be removed. The top flap can be slid out, then turn the

turbine and remove each flap as it reaches the top position.

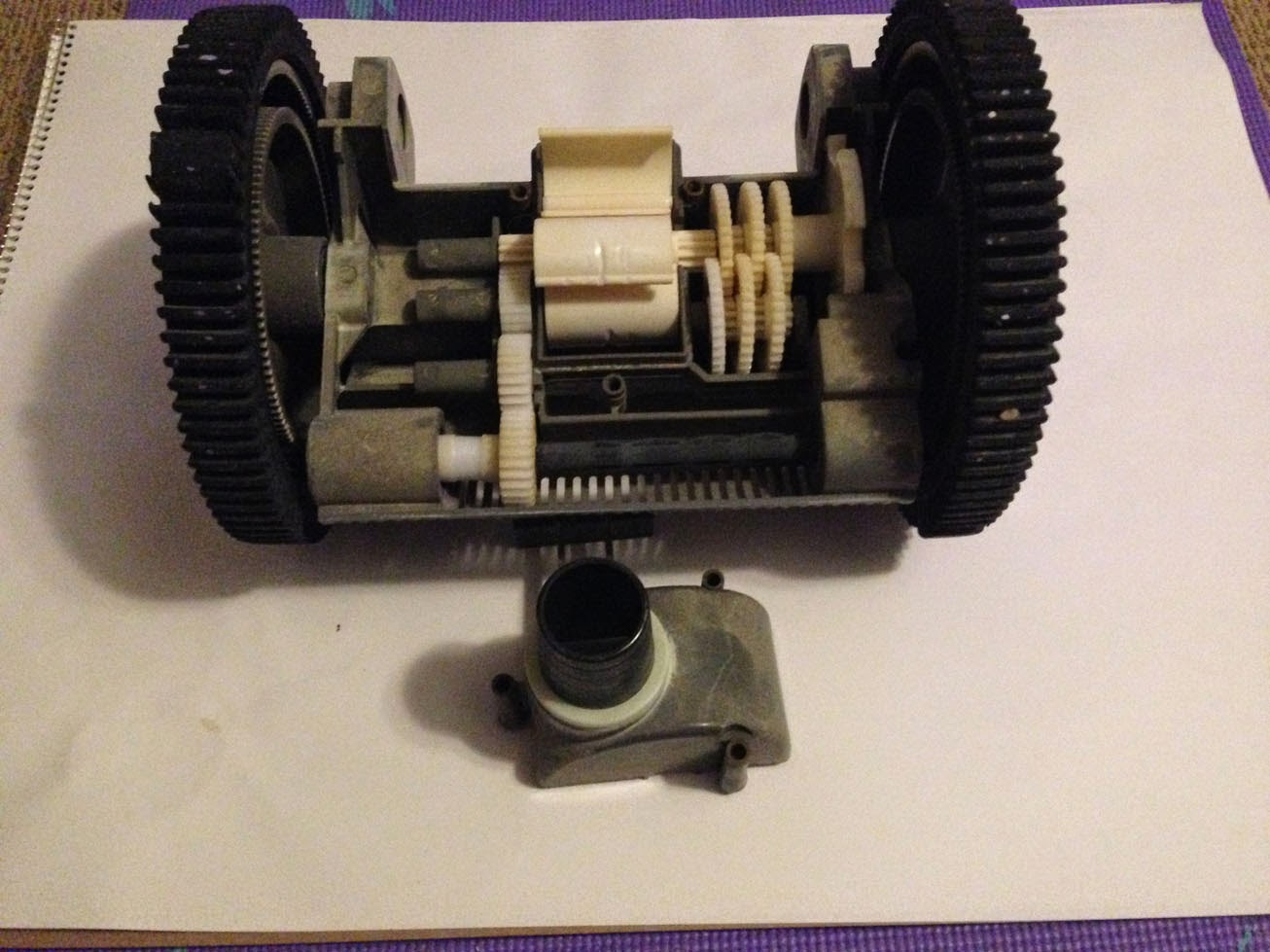

Both wheels need to be removed to expose the rod holding the

turbine in place. Use the Allen wrench to remove the single screw holding each

wheel to the cleaner.

The rod holding the turbine needs to be pushed though the

pool cleaner. This will be the most

difficult part of the install. The rod will come out on the side with four

small gears in a single line. Depending on the age of the unit, this rod might

have rusted in place.

In this specific case, as shown a hammer and screwdriver

were used to force the rod out of position, freeing the center turbine. Once

the rod is out, the turbine can be pulled out of the cleaner.

A picture of the old and new turbines for comparison.

The new turbine is placed into the old turbine’s position

with the flaps falling towards the front of the cleaner.

The rod now needs to be pushed into the cleaner from the opposite

direction from which it was removed. When the rod gets to the turbine, the

turbine will need to be held up to line up the rod with the turbine’s center

hole.

This rod also holds the back 3 gears in place, so as the rod

gets to each one, they will need to be held up in position for the rod to pass

though them. Needle nose pliers can be used to help grab and hold these up one

at a time.

To get the rod completely in, it was hammered back into

place. Once it is fully inserted, the rod should not be visible when viewed

from above.

Both wheels were reattached to the cleaner.

The center cone is placed back over the turbine (it will

only fit on one way)

The top shell is placed back on the cleaner, and the three

Phillips head screws are placed back in to secure it down.